First, the scope of application:

This device is designed to test the compatibility between specific aggregate grades and modified emulsified asphalt. It uses a single-phase asynchronous motor, a reducer, and a chain drive system to rotate the bottle around its axis while the test specimen moves between the rotating bottle and water.

It is compliant with JTG E20—2011 "Testing Procedures for Asphalt and Asphalt Mixtures for Highway Engineering" T0758-2011, which outlines the procedure for determining the compatibility grade of slurry mixtures.

Second, the structure and features:

The equipment consists of a single-phase asynchronous motor, a reducer, a chain drive, a rotating mechanism, and a rotating bottle installation. The electrical system includes a counter and a proximity switch, ensuring a neat and professional appearance.

Third, technical parameters and specifications:

Dimensions: 100 × 735 × 705 mm

Rotation speed: 20 r/min

Maximum running speed: 9999 × 100 rpm

Maximum number of test pieces: 8

Maximum running time: 8 hours (actual operation: 3 hours)

Power supply voltage: 380V (50Hz)

Fourth, installation and commissioning:

1. Install and wire the electrical control panel.

2. Mount the spindle by fixing the rotating frame on the main shaft, installing a flat key, and securing the sprocket to the main shaft using the same key. Fix the end of the main shaft away from the sprocket to the bearing on the seat. Ensure the sprocket is fixed through the chain box hole, and secure the bearing housings on both sides of the side bearing to the main frame, chain coupling, and reducer sprocket.

3. Adjust the chain tension by adjusting the reducer base to secure the reducer bracket and bearing bracket.

On the control panel, from left to right, you will find: counter, reset button, start button, stop button, and power main switch. The counter can be set from 0 to 9999 × 100 and has a power-down memory function. To restart, press the reset button to return to zero.

To perform the test, first fill the rotating bottle with 3/4 of water, then place the test piece inside, cover the cap with an O-ring, and align the middle hole at the bottom of the bottle with the tip of the fixed end on the rotating frame. Align the center hole on the cap with the tip of the grip knob, and turn the knob to tightly secure the cap. Repeat this process for the other bottles. After installation, close the front door and the upper cover. Set the counter value (usually 3600, meaning three hours), press the reset button to zero it, and then press the start button to begin the test. When the counter reaches the set value, the device will stop automatically, completing the test.

Sixth, equipment maintenance:

1. Grease the bearings once a year in May and November.

2. Apply grease to the chain every three months.

3. Replace the gear unit annually.

4. After each test, clean the rotating bottle thoroughly to ensure accuracy and longevity of the equipment.

Welcome to OREMA's exclusive range of Front Terminal Batteries – the ideal choice for those who prioritize efficiency, space-saving design, and unwavering reliability in their power needs.

Innovative Design for Effortless Installation and Service

Our OREMA UNF series front terminal batteries redefine convenience with their integrated handles and accessible front terminal connections. Designed for seamless integration into both 19-inch and 23-inch battery cabinets, these batteries promise hassle-free installation and maintenance – a perfect fit for industrial, utility, and telecommunication settings.Advanced AGM Technology: Power, Performance, and Peace of Mind

At the heart of our OREMA UNF series lies the AGM (Absorbent Glass Mat) technology. This innovation encapsulates the electrolyte in glass fiber mats, offering enhanced performance and maintenance-free operation. Known for their high reliability and longevity, these batteries are the go-to solution for critical backup power requirements.Features of OREMA Front Terminal Storage Battery

Easy Installation & Space Efficiency: With front access terminals, our batteries simplify installation and servicing, saving you time and space.High Energy Density: Our batteries deliver superior performance while occupying less space, enhancing energy density.

Exceptional Discharging Ability: Thanks to radial grid design and tight assembly technology, these batteries excel in high-rate discharge performance.

Longer Float Service Life: Enjoy over 8 years of reliable service at 25°C, backed by unique corrosion-resistant grid alloy.

Maintenance-Free Operation: Our AGM technology ensures efficient gas recombination and eliminates the need for electrolyte maintenance.

Low Self Discharge: High purity raw materials reduce self-discharge, ensuring longevity.

Environmental & Nonpolluting: Our batteries feature Gas Recombination technology, preventing acid fog emissions.

Safe & Reliable: An efficient venting system releases excess gas and reseals valves, safeguarding against bursting.

Versatile Applications of OREMA Front Terminal AGM Battery

Our Front Terminal Batteries are designed for diverse applications including:19inch/23inch standard power supply cabinets

Communication Systems (Switches, Microwave Stations, Mobile Base Stations, Data Centers, Radio/Broadcasting Stations)

Special or LAN Power Supply Systems

Signal, Emergency Lighting, EPS & UPS Systems

Broadband, Electric Utility, Telecom, Central Office, Fire Alarms, and Security Systems

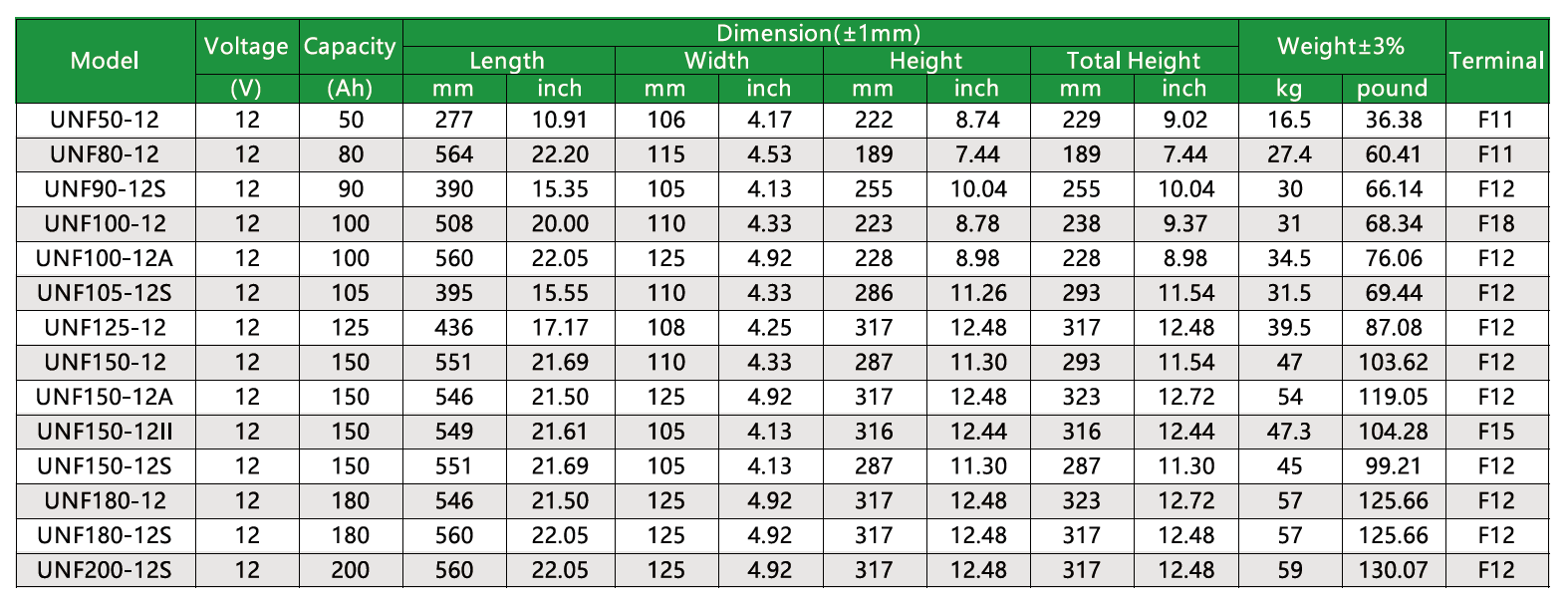

Specifications of the OREMA UNF series 12V Front Terminal Batteries:

Tailored Solutions with OREMA's Expertise

With 20 years of innovation in sealed lead-acid battery manufacturing, OREMA stands as a rising star in the industry. Our commitment to quality is unwavering, as evidenced by our comprehensive quality management system. Embracing unity, growth, trust, and quality-first ethos, our team is dedicated to providing top-tier power solutions and personalized services. Meeting and exceeding customer expectations remains our perpetual goal.

Front Terminal Batteries,front terminal sla battery,front terminal storage battery,front terminal agm battery,12V front terminal batteries

OREMA POWER CO., LTD. , https://www.oremapower.com